Customized product development

We offer custom and development solutions for wireless charging products, and we can complete such projects in a a few months-we know that it is important to be able to respond to market trends in a short time.

Our perfectly aligned team of engineers and product designers continuously develops and realizes new, innovative technical solutions. We place immense importance on comprehensive and growing expertise and of course deploy state-of-the-art machinery.

Some of the products for which we have developed solutions are:

- Inductive charging solution

- Desktop wireless charger

- Stand wireless charger

- Car wireless charger

- Magnetic wireless charger

- Long Distance Wireless Charger

- And other (specific to wireless charging products) solutions

-

quality

All product quality is strictly implemented in accordance with the requirements and passed multi-level testing and evaluation. -

speed

We take the process from idea to series solution in just a few months. Thanks to our structured project management, we are able to also expeditiously implement your requests . -

flexibility

We respond flexibly to our customer’s and the market’s demands. Joining forces with Lantaisi as your partner will enable you to exp editiously respond to market developments. -

OEM Standards

We will be pleased to handle the qualification and validation or homologation in compliance with OEM standards.

- ldea

- ID

- EVT

- DVT

- PVT

- MP

From idea to solution to production in a short time

As a system supplier, wwe take care of all required steps. The process begins with project planning, 2D product renderings, 3D prototype construction, and continues with the verification and validation based on OEM criteria and ends with series production. All quality determining project steps are completed in Lantaisi .

-

idea

Regardless of whether you already have a very concrete concept or just a vague idea – project planning with us begins with a detailed pre-project meeting. -

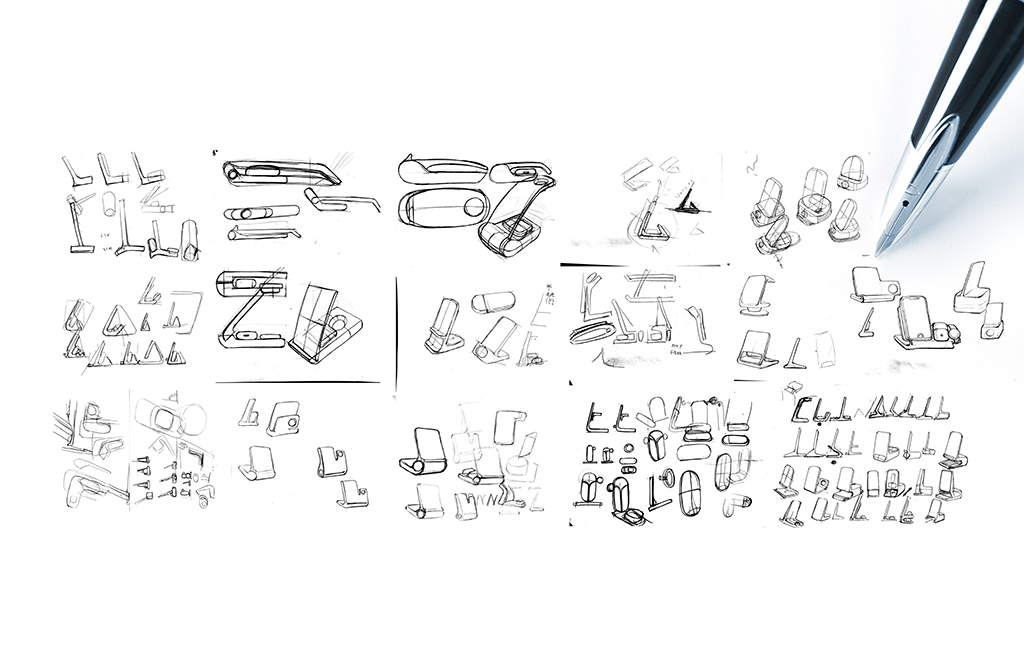

ID (Industrial Design)

Product design engineers make product renderings based on customers’ ideas, show the design concepts to customers, and let your ideas take shape. -

EVT (Engineering Verification Test)

After you accept the appearance shown in the product renderings, we will conduct design verification at the initial stage of product development. This includes functional and safety testing. Generally, RD (R&D) conducts a comprehensive verification of samples and conducts multiple tests to ensure product safety. -

DVT (Design Verification Test)

Design verification testing is an indispensable testing link in hardware production. We will conduct mold testing, electronic performance testing, and appearance testing. After solving the problems of the sample in the EVT stage, the level and timing of all signals are tested, and the safety test is completed, which is verified by RD and DQA (Design Quality Assurance). At this time, the product is basically finalized, and we will conduct 3D proofing and open the mold. -

PVT ( Pilot-run Verification Test)

When the customer confirms that there is no problem with the size and structure of the sample model, we will conduct a trial production to verify the realization of the functions of the new product d and conduct stability and reliability tests. The test results are no problem and the samples will be mailed to the customer. -

MP(Mass Production)

If there is no problem with the sample, our production department can carry out mass production for you at any time. We have a complete supply chain system: integrated management of factory workshops, research and development equipment, production equipment, warehousing and transportation. It is our company’s mission to make customers worry-free.

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur